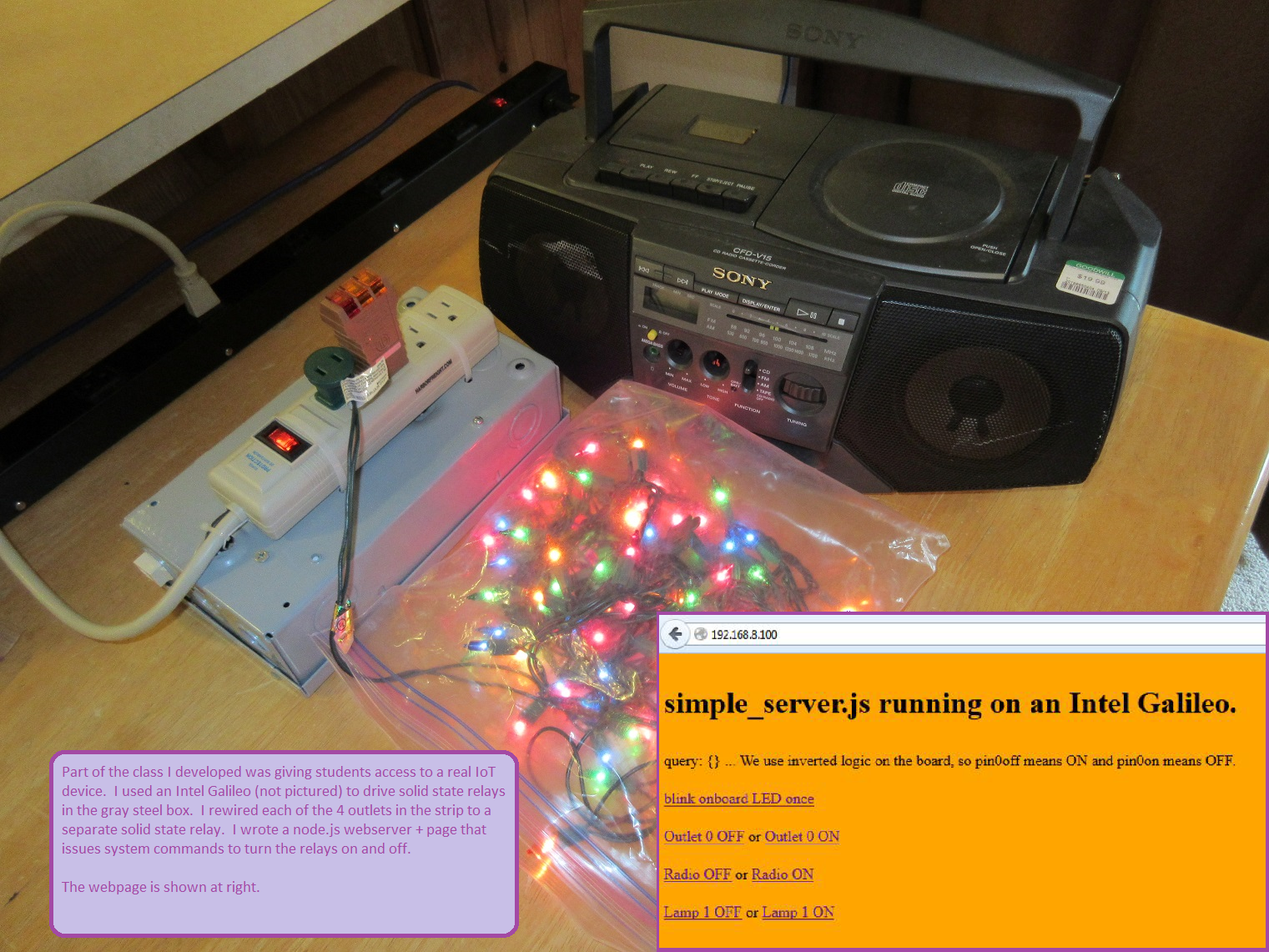

My Simple Server IoT device is:

| Senior Hardware Design Engineer Automating Engineering, Beer, and Gaming. |

qtpierce@gmail.com LinkedIn: www.linkedin.com/in/quentin-t-pierce Resume: http://www.smegabyte.dyndns.org/resume/ |

||

I

enjoy making beer. But it is labor intensive and prone to error.

I wanted automation to take over the following tasks:

If automation could perform those tasks, then I would be freed up to do other things while it made beer. I would then have minimal interaction with the mechanics of the process. The Beer Machine uses an Arduino microprocessor to control solid-state-relays and read temperature sensors. |

The result is: I can truly multitask while hobbying.

|

||

|

What is the coolest thing about the Beer Machine? It's versatility. |

Does home automation work? Yes, nicely. |

|

Since I finished the prototype, I have:

|

Friends rave about the brisket and then ask me if I spent all night tending a fire. No, I don't. The process is:

|